FMR67 Radar Tank Gauge

The FMR67 Radar Tank Gauge (RTG) is a smart, 80 GHz radar tank gauge for continuous and non-contact level measurement with an accuracy rate of ±1 mm for liquids and ±3 mm for solids.

- Overview

- Specifications

- Options

- Resources

- Related Products

Accurately Measure Your Inventory

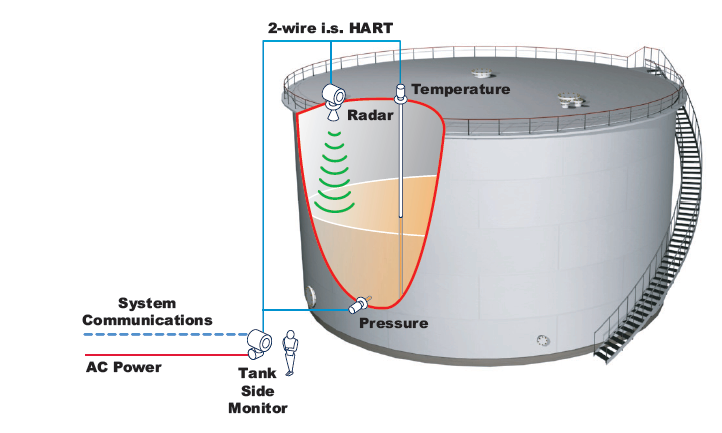

FMR60 RTG, with an accuracy level of ±1 mm for liquids and ±3 mm for solids, is a 2-wire technology that reduces tank wiring costs and allows easy implementation into existing systems. With its non-contact measurement, the tank’s top is almost independent from product properties.

FMR60 RTG, with an accuracy level of ±1 mm for liquids and ±3 mm for solids, is a 2-wire technology that reduces tank wiring costs and allows easy implementation into existing systems. With its non-contact measurement, the tank’s top is almost independent from product properties.

Touch Screen Operations

Easy onsite operation using built-in touch control display without having to open the enclosure. It also has a user friendly operating menu.

Bluetooth® Enabled

The FMR62 has Bluetooth® wireless technology for for commissioning, operation, and maintenance via free iOS/Android app SmartBlue, with optional BT10 Bluetooth module.

Worldwide Approvals

Worldwide Approvals

Each radar gauge is approved for use in explosion hazardous areas to FM, CSA, ATEX, IECEx, NEPSi, KC, INEMETRO, JPN, and TIIS standards. They are also SIL 2 and SIL 3 rated for overfill prevention.

Key Features

- 2-wire technology: Reduces on tank wiring costs and allows easy

implementation into existing systems - Non-contact measurement: Tank top is almost independent from product

properties - 2″/50 mm PTFE drip-off antenna, or 3”/80 mm PTFE flush mount antenna

- Purge air connection for cleaning in extreme conditions, NPT 1/4″ or G 1/4″

- Standard range to 164 ft (50m) with the 2” antenna, or up to 410 ft (125

m) with the 3” antenna - Easy on-site operation using built-in touch control display without opening

enclosure (or optional push button display with cover removed) - Access historic data from device integrated memory (HistoROM) and

transfer configuration setting from device to device - Easy commissioning and diagnostics using Windows® based software

- HART protocol

- High temperatures: Suitable for process temperatures from -40° C (-40° F),

up to 200° C (392° F) with high-temperature seal and antenna - Pressure: -1 to +16 bar (-14.5 to +232 psi)

- Approved for use in explosive hazardous locations

- Optional: Integrated over voltage protection

- SIL 2 approved for overspill protection system applications or SIL 3 for

standalone applications - Optional remote display (FHX50)

- Bluetooth® wireless technology for commissioning, operation, and

maintenance via free iOS/Android app SmartBlue, with optional BT10

Bluetooth module

Accuracy

Measuring distance up to 0.8 m (2.62 ft): max. ±4mm (±0.16 in) – digital, ±0.03% analog

Measuring distance > 0.8 m (2.62 ft): ±1 mm (±0.04in), digital, ±0.02% analog

Non-repeatability – ≤ 1 mm (0.04 in)

Power Consumption

- 2-wire; 4-20mA HART: < 0.9 W

- 2-wire; 4-20mA HART, switch output:< 0.9 W

- 2-wire; 4-20mA HART, 4-20mA: < 2 x 0.7 W

Current Consumption

HART:

Nominal current: 3.6 to 22mA. The start-up current for multidrop mode can be parametrized

(is set to 3.6mA on delivery)

Breakdown signal (NAMUR NE43): adjustable: 3.59 to 22.5mA

Weight

3.2 – 3.9 kg (7.11 – 8.61 lb) plus flange weight

Enclosure

Degree of protection:

- With closed housing tested according to:

- IP68, NEMA6P (24 h at 1.83 m under water surface)

- For plastic housing with transparent cover (display module): IP68 (24h at 1.00 m under

water surface) - IP66, NEMA4X

- With open housing: IP20, NEMA1

- Display module: IP22, NEMA2

- Housing GT19: plastic

- Housing GT20: aluminium, seawater repellent, powder coated

Antenna

IP 68 (NEMA 6P)

Ambient Temperature

Unit: -40 °F and +176 °F (-40 °C and +80 °C)

Display: -4 °F and +158 °F (-20 °C and +70 °C)

Operating Frequency

Approx. 80 GHz, up to 8 devices can be installed in the same tank

Approvals

FM, CSA, ATEX, IECEx, NEPSi, KC, INEMETRO, JPN, and TIIS

Approvals and Certifications

FM, CSA, ATEX, IECEx, NEPSi, KC, INMETRO, JPN, and TIIS

Seals

- FKM Viton GLT, -40 to 80 °C ( -40 to 176 °F), for Drip-off, PTFE 50mm/2″

antenna - FKM Viton GLT, -40 to 150 °C ( -40 to 302 °F), for PTFE flush mount, 80 mm /

3″ antenna - FKM Viton GLT, -40 to 200 °C ( -40 to 392 °F), for PTFE flush mount, 80 mm /

3″ antenna

Process Connections

- NPS 3″ or NPS 4” Cl.150 RF, 316/316L flange ASME B16.5

- DN80 or DN100 PN10/16 B1, 316L flange EN1092-1

- Thread ANSI MNPT1-1/2, 316L

- Thread ISO228 G1-1/2, 316L

- 10K 80A or 100A RF, 316L flange JIS B2220

- Align. device, UNI 4″/DN100/100, Alu, max 14.5lbs/PN1/1K, suitable for 4″

150lbs/DN100 PN16/10K 100 - Align. device, UNI 6″/DN150/150, Alu, max 14.5lbs/PN1/1K, suitable for 6″

150lbs/DN150 PN16/10K 150 - Align. device, UNI 8″/DN200/200, Alu, max 14.5lbs/PN1/1K, suitable for 8″

150lbs/DN200 PN16/10K 200 - Align. device, UNI 10″/DN250/250, Alu, max 14.5lbs/PN1/1K, suitable for 10″

150lbs/DN250 PN16/10K 250 - UNI flange 3″/DN80/80, 316L or PP, max 4bar abs/58psia, suitable for NPS 3″

Cl.150/DN80 PN16/10K 80 - UNI flange 4″/DN100/100, 316L or PP, max 4bar abs/58psia, suitable for NPS

4″ Cl.150/DN100 PN16/10K 100 - UNI flange 6″/DN150/150, 316L or PP, max 4bar abs/58psia, suitable for NPS

6″ Cl.150/DN150 PN16/10K 150 - UNI flange DN200/8″/200, 316L max PN1/14.5lbs/1K, suitable for NPS 8″

Cl.150/DN200 PN10 PN16/10K 200 - UNI flange DN250/10″/250, 316L max PN1/14.5lbs/1K, suitable for NPS 10″

Cl.150/DN250 PN10 PN16/10K 250

Output Options

HART

Gland Entry

Metric, NPT, G

Languages

Over 15 national languages available

Datasheet

Technical Specifications

Brochure

Application Checklists