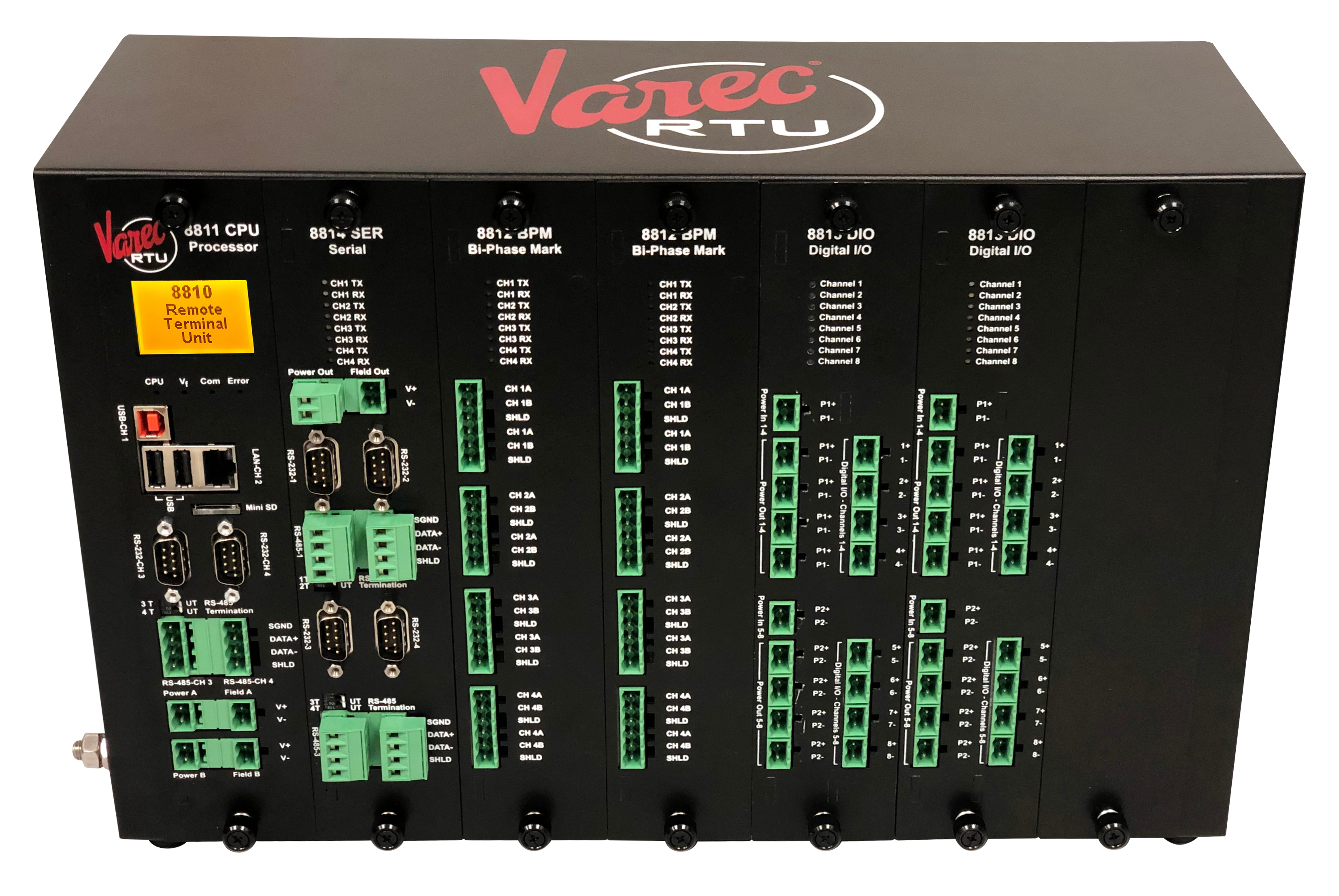

8810 Remote Terminal Unit

The 8810 Remote Terminal Unit (RTU) is a modular, Ethernet enabled, communications device. Its powerful industrial chassis is ideal for integration with tank gauges and other field devices used in inventory management applications. With support for up to six interface modules, it is extremely flexible in handling data exchange across multiple communication protocols.

- Overview

- Specifications

- Options

- Resources

- Related Products

Next Generation Communications Device

With the CPU module serving as the base functionality for the 8810 RTU, all logic and protocols are handled seamlessly, meaning there is only one firmware application for the entire unit.

The standard, built-in OPC Unified Architecture (OPC UA) server communicates natively over standard internet protocols. This allows human machine interface (HMI) applications to read data from the 8810 RTU. It is also compatible with a wide range of systems, including legacy Varec systems, using RS-232 and RS-485 standards.

8810 RTU Key Features:

- Ethernet enabled, provides high-speed communications in near real time

- Industry standard OPC UA

- 800 MHz, 4-core CPU

- Multi-threaded task handling

- Modbus for host or field integration via Serial RTU, Modbus TCP, or Modbus

over TCP - Channels can be configured as Modbus Slave or Master

- Supports up to 400 tanks

- Supports up to 24 communication channels

- Digital input/output for alarms, monitoring and control

- Intelligent scanning based on tank activity

- Offline configuration functionality

- Pre-configured diagnostics built-in

- Interfaces with multiple different manufacturer’s tank gauging devices

- Optional tank volume calculations based on the latest API standards

- Supports remote firmware upgrades and file transfers

- Includes the Vertue browser-based configuration application

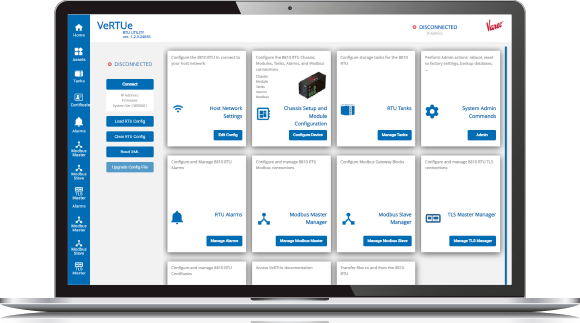

VeRTUe RTU Utility

The 8810 RTU comes with its own configuration application. Vertue is intuitive, extremely user-friendly and browser-based.

Key Features:

- Standard with 8810 RTU for configuration

- Intuitive browser-based user interface

- Optimized for bulk liquid applications

- Configure using any workstation on the network

- Efficiency tools for common actions

- Supports offline configuration

- Pre-configured or customized diagnostics

Add-on Modules

The following add-on modules* are available as options: Serial, GPU Bi-Phase Mark, Digital I/O, Mark/Space, Tankway, and Analog Input.

Other protocols supported through the Serial module include Veeder Root, Hectronic and Ronan.

GPU Bi-Phase Mark Module (8812):

- Supports connection and communication to Honeywell Enraf GPU Bi-Phase Mark loops

- Provides four interface ports per module

- Each port includes two termination plugs

- Individual surge protection for each channel

- LED indicators denote status for each channel, i.e. transmit and receive

Digital I/O Module (8813):

- Logic and digital signal processing handled by the CPU module

- Includes eight ports for interfacing with digital I/O circuits

- Each channel is individually configurable as input or output

- Supports integration of digital signals such as alarms

- LED indicators denotes status for each channel, i.e. transmit and receive

- Optional Watchdog is an independent digital output signal triggered by a hardware failure, event or alarm

Serial Module (8814):

- 4 serial channels, each independently configured for RS232 or RS485

- Channels can be configured as Modbus Slave or Master

- User configurable master and slave maps allows integration or retrofit/mimic to any system

- Support for user mappings of Modbus registers to 8810 RTU tags and parameters

- Built-in standard slave map for typical tank data (Level, Temperature, and Status)

- Built-in tank points for tank gauge communication, but also custom configuration for any Modbus device

- Supports host communications via the GPU protocol over RS-232/RS485 to Enraf CIU devices

- Supports RTU protocol for legacy FuelsManager® Systems

- Individual surge protection for each channel

- LED indicators denote status for each channel, i.e. transmit and receive

- Enables support for Veeder Root, Hectronic and Ronan protocols

Mark/Space Module (8815):

- Integrates to multiple Varec transmitters

- Integrates to third party manufacturer transmitters that talk Mark/Space

- Two independent Mark/Space channels

- Supports Mark/Space transmitters configured for high speed or low speed communications

- Supports communications to Mark/Space transmitters configured for level and temperature (56-bit), or level only (40-bit)

- Flexible power distribution as each channel can be independently powered by the 8810 back plane or an external power supply

- 2500 V(rms) isolation enables a given channel to take a significant surge without impacting surrounding channels

- Each channel has a replaceable fuse

- LED indicators denote status for each channel, i.e. transmit, receive, power selection/fuse and bus failure

Tankway Module (8816):

- Two independent Tankway channels

- Supports L&J Tankway tank gauge transmitters

- Flexible power distribution as each channel can be independently powered by the 8810 back plane or an external power supply

- Each channel has a replaceable fuse

- 2500 V(rms) isolation enables a given channel to take a significant surge without impacting surrounding channels

- LED indicators denote status for each channel, i.e. transmit, receive, power selection/fuse and bus failure

Analog Input Module (8818):

- Analog input signal processing handled by the CPU module

- Includes eight channels for interfacing with analog instruments

- Each channel is individually configurable

- Supports conversion of analog signals into alarms and tank points

- Compatible with 4-20 mAmp transmitters, 0-5 Volt signals, loop-powered or self-powered signals, and differential or single-ended signals

- Each channel provides current limiting for loop-powered signals

- Individual surge protection for each channel

- Each channel has a replaceable fuse

- LED indicators denote status for each channel, i.e. transmit, receive, power selection, and bus failure

FSK Frequency Shift Keying Module (8819):

- Supports connection and communication with Emerson (SAAB) Rex/Raptor/Pro RADAR tank gauges, DAU local display / Multiple Spot Thermometer input, along with the 2410 Tank Hub

- Two transformer-isolated channels per interface module

- Two 3 position pluggable (removable) terminal block per channel for convenient connection of field wiring

- A maximum of 20 tanks may be connected on a single interface module via the Rosemount Modbus TRL/2 protocol that utilizes a Frequency Shift Keying signaling method

- 4 LED indicators each for CH1 and CH2; Tx (Transmit), Rx (Receive), CD (Carrier Detect), ENABLE

- Utilize Varec’s VeRTUe software for configuration of the 8819 FSK module

*Additional enhancements currently under development.

Integrates with HMI Applications

Integrates with HMI Applications

The 8810 RTU can be integrated with a variety of human machine interface applications. FuelsManager, a suite of software applications used to track, manage and control the receipt, storage, distribution and delivery of fuel and related products, has built-in functionality for easy integration with the 8810 RTU. Examples of other supported HMI manufacturers include Honeywell, Rockwell Automation, Emerson and Wonderware.

Industry Approvals

The 8810 RTU meets radiated and immunity certifications for the following:

- United States – FCC

- Canada – IECS

- Europe – CE and RoHS

Module Architecture

• Complete Computer Control System

• Inputs are reported to Host Computer by Scanned Poll

• Built-in Software Function Library

• Surge Protection Conforming to ANSI/IEEE C37.90a-1974

• Host Communication via RS-232 and RS-485

• Industry Standard Protocols: Modbus and OPC UA

• I/O Interfaces: DI, DO

• Quick-Disconnect I/O Terminations

• Modular Construction for Optimum Expandability

• Non-Volatile Database

• Redundant power inputs

• 6 expansion slots

• 24+ channels (more for DIO)

• Supports up to 400 tanks

• Green Hills INTEGRITY RTOS with ARINC-653 Partitioning

• NIST SP 800-53 & FIPS 140-2 Compliant (future)

I/O Expansion

The available expansion modules are listed below:

• 8812 BPM: Bi-Phase Mark

• 8813 DIO: Digital I/O

• 8814 SER: Serial

• 8815 M/S: Mark/Space

• 8816 TW: Tankway

• 8818 AI: Analog Input

• 8819 FSK: Frequency Shift Keying

Memory

• 800 MHz quad-core CPU

• 1 x 32 GB USB flash drive

• 2 x 32 GB mini SD cards

• 2048 MB high-speed RAM

DC Power

18-60 VDC, 20 W max (CPU Module)

TCP/IP Communications

100 Mbps Ethernet interface using OPC UA over TCP/IP and Modbus over TCP

Serial Host/Slave Communications

• Selectable Data Rate, 1200 to 115200

• RS-232 or RS-485 communications

• RS-485 Maximum Cable Length (18 AWG), 4000 ft/1200 m

• RS-485 Maximum Multi-dropped Units: 32

Physical

8810 RTU Case: 15.50″ W x 9.85″ H x 6.00″ D

Environmental

• Operating Temperature: -40°F to 185°F; -40°C to +85°C

• Storage Temperature: -40°F to 212°F; -40°C to 100°C

• Humidity: 0 to 95% RH non-condensing

• Ingress Protection: NEMA 1, IP30

Discrete Inputs/Outputs

• Maximum Quantity: 48

• Isolation Voltage: 4000 Vrms

• Maximum Current: 2.0 A

• Operating Voltage:

– Output: up to 60 VDC

– Input: up to 60 VDC

Datasheet

Technical Specifications

Brochure

Manuals