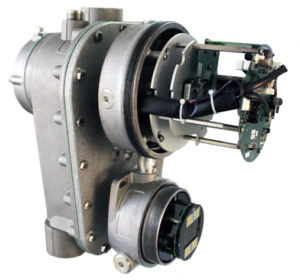

2920 Float & Tape Transmitter

The 2920 Float & Tape Transmitter (FTT) provides data from the tank side to the control room for use in inventory management applications. It accurately converts mechanical level measurement from the connected tank gauge, integrates temperature and HART devices, and provides digital inputs and digital outputs for the indication of alarms or drive relays.

- Overview

- Specifications

- Options

- Resources

- Related Products

Touch Control

A digital display with capacitive touch control interface provides inventory information at the tank side and configuration of the transmitter for all connected devices. Each parameter, such as communications, baud rate, unit address, etc., is easily configured using the touch screen display.

Absolute Accuracy and Reliability

The 2920 FTT utilizes an absolute capacitance encoder and precision direct-drive gearing to accurately convert the mechanical level measurement from the connected tank gauge – the most accurate encoder technology on the market today. Furthermore, the encoder requires no service, no battery back-up and contains no parts that can wear out over time.

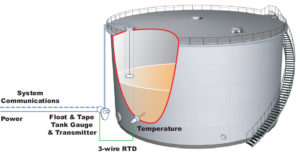

On Your Tank

The 2920 FTT is easy to install. It mounts directly to most mechanical tank gauges, (Varec, GSI, L&J, Sakura) and integrates into existing tank gauging communication loops (MODBUS®, Biphase Mark, Mark/ Space and Tankway).

Complete Tank Gauging System

The 2920 FTT integrates ancillary equipment, and sensors, and provides the first steps to automation and control. It supports up to 4 HART devices and provides an on‐board 3‐wire RTD temperature input. It can activate alarms or relays using analog and digital inputs/outputs, SPDT cam-operated outputs and software-driven contact outputs.

Training and Support

The 2920 FTT is available to ship today. Every transmitter is supplied with detailed user instructions, but sometimes you need to see how it’s done. That’s why we also have a YouTube channel with basic how-to-videos. If you need direct support, we offer standard training and service programs that we tailor to your staff, and your facility.

Accuracy & Repeatability

± 1/16″ (1.58 mm)

Range

0 to 120 ft; Meters: 0 to 36 m

Limit switch range is 100 ft (30 M) maximum

Communications

Mark/Space

EIA‐485/GSI Type MODBUS®

Biphase Mark

L&J Tankway

Power

Standard: 20 to 65 VDC 0.05A

Optional: 40 to 65 / 110 / 220 – 240 VAC

750 mW nominal, 50/60 Hz

Built-in galvanic isolation for both AC and DC models

Temperature Input

High‐accuracy 20‐bit analog‐to‐digital converter. 3‐wire RTD Copper (CU90, CU100) or Platinum (PT100).

Discrete Inputs

Enables connection to ancillary devices, such as switches, pumps or valves

Standard: (DC Unit) Option: Two (2) discrete inputs.

Optional: (AC Unit): 4 discrete inputs

Host signal: Open/Closed

Contact Outputs

Optional (AC Unit): Four (4) software-driven contact outputs

Host Signal: Open/Closed

Rated load: Resistive load with p.f = 1.0, 0.30 A at 125 VAC, 1 A at 30 VDC

Inductive load with p.f. = 0.4, 0.20 A at 125 VAC, 0.50 A at 30 VDC

See Installation & Operation Manual for additional specifications.

I/O

Analog Input (x1) 4 to 20 mA

Analog Output (x2) 3.5 to 22 mA

HART

HART master for ancillary devices

Typically 4 max, depending on current consumption

Limit Switches

11 amp ‐ 125, 250, 277 VAC

4 amp ‐ 125 VAC Tungsten filament Lamp

Load: 1/3 HP ‐ 125 VAC, 250 VDC

Load: 1/2 amp ‐ 125 VDC, 1/4 amp ‐ 250 VDC

Approvals

cFMus (USA & Canada) ‐ Explosion proof: Class I, Division 1, Groups C&D T5 ‐25 °C ≤ Ta ≤ +85 °C

Flameproof, Class I, Zone 1, AEx/Ex d IIB T5 ‐20 °C ≤ Ta ≤ +85 °C

ATEX/IECEx (International) – Flameproof, Class I, Zone 1, Ex II 2G, Ex d IIB T5 Gb ‐20 °C ≤ Ta ≤ +85 °C

For complete technical specifications, download the technical document or product manual.

01 Approvals

02 Power Input

03 Communications

04 Limit Switches

05 Limit Switch Range

06 Digital I/O

07 Analog I/O

08 HART

09 Display Orientation

Video

Datasheet

Manuals

Parts and Accessories

Technical Specifications

Certificates

Case Study

Brochure

White Paper