8920 Loop Powered Transmitter

8920 Loop Powered Transmitter (LPT) – View accurate level and temperature data at the tank side and transmit it to the control room via 4-20mA or HART (Pending)

- Overview

- Specifications

- Options

- Resources

- Related Products

Highlights

- Digital display with capacitive touch control interface provides

inventory information at the tank side and configuration of the

transmitter for all connected devices - Easy in-service installation – mounts directly to most mechanical tank gauges, including Varec, L&J, and GSI

- Activate alarms or relays with; 2-4 SPDT cam-operated switches (as option)

- Approved for hazardous areas: cFMus, ATEX, IECEx, UKEx

Applications

Applications

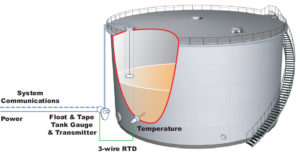

For use in inventory management applications, the 8920 Loop Powered Transmitter (LPT) is a precision transmitter designed to relay level or level & temperature information via field communications to the control room. Changes in liquid level and tank temperature are output to a 4-20 mA signal, or via HART (pending). The 20-to-48 DC voltage required for operation may be supplied by the user or through an optional 85-to-305 VAC on-board power supply. Two or four cam-operated switches that can be utilized for indication of alarms or relays are also available as an option.

On Your Tank

The 8920 LPT is easy to install. It mounts directly to most mechanical tank gauges (Varec, GSI, L&J, Sakura).

Complete Tank Gauging System

The 8920 LPT integrates ancillary equipment, and sensors, and provides the first steps to automation and control. It provides an on‐board 3‐wire RTD temperature input. It can activate alarms, SPDT cam-operated outputs, and software-driven contact outputs.

Training and Support

The 8920 LPT is available to ship today. Every transmitter is supplied with detailed user instructions, but sometimes you need to see how it’s done. If you need direct support, we offer standard training and service programs that we tailor to your staff, and your facility.

Accuracy & Repeatability

1 / 16 ” (1.58 mm)

0.16% over full range

Range

Standard ranges /min and max of 0 to 120 ft

Standard ranges/ min and max of 0 to 36 m

Communications

Single 4-20 mA Output (Level only)

Dual 4 – 20 mA Output (Level and Temperature)

HART Output (Level and Temperature) (Pending)

Power

Operating voltage range 20 – 48 VDC (regulated)

2 W from external power supply

OR

85 to 305 VAC 50/60 Hz, 4.5W

Temperature Input

High accuracy 20-bit analog-to-digital converter. 3-wire RTD Platinum (PT100)

Limit Switches

2 or 4 SPDT limit switches (optional)

11 amp – 125, 250, 277 VAC

1/3 HP – 125 VAC, 250 VDC

½ amp – 125 VDEC, ¼ amp – 250 VDC

4 amp – 125 VAC Tungsten Filament Lamp Load

For complete technical specifications, download the technical document or product manual.

01 Approvals

| AC | IECEx (Low Temp): Ex db IIB T5 Gb ATEX/UKEx (Low Temp): Ex II 2 G Ex db IIB T5 Gb -40 °C ≤ Ta ≤ +73 °C |

| FC | cFMus (USA & Canada) Class I, Division 1, Groups C&D, T5, ‐40 °C ≤ Ta ≤ +73 °C, Type 4 Class I, Zone 1, AEx db IIB T5 Gb, ‐40 °C ≤ Ta ≤ +85 °C, IP66 (USA) Ex db IIB T5 Gb, ‐40 °C ≤ Ta ≤ +85 °C, IP66 (CAN) |

| FM | cFMus (USA & Canada) Class I, Division 1, Groups C&D, T5, ‐25 °C ≤ Ta ≤ +73 °C, Type 4 Available with External Display options only |

02 Power Input

03 Communications

04 Limit Switches

05 Limit Switch Range

06 Display Orientation

Manuals

Brochure