9810 Mini Remote Terminal Unit

The 9810 mini Remote Terminal Unit (miniRTU) is a member of Varec’s comprehensive range of industrial communication interfaces, building on the proven reliability of the 8300 TGI (Tank

Gauge Interface) and 8810 RTU. Its compact design allows for easy placement in the same space as an existing 8300 TGI. The 9810 miniRTU is a cost-efficient single field protocol option to the 8810 RTU.

- Overview

- Specifications

- Options

- Resources

- Related Products

Next Generation Communications Device

The standard, built-in OPC UA server communicates natively over standard internet protocols. This allows human-machine interface (HMI) applications to read data from the 9810 miniRTU. The 9810 miniRTU is also compatible with a wide range of systems, including legacy Varec systems, using RS-232 and RS-485 standards.

9810 RTU Key Features:

- Ethernet-ready, provides high-speed, real-time communication capabilities

- Industry standard Ethernet supports OPC UA, Modbus TCP, and Modbus over TCP

- Modbus for host or field integration

- Supports multiple communication ports and protocols

- Scans for level, temperature, and status information

- Compact form factor

- Designed for small-to-medium tank farms

- Fully compatible with FuelsManager®

- Supports up to 32 tanks with volume calculations

- Integrates with legacy tank gauging interfaces (Serial, Bi-Phase Mark, Mark/Space, Tankway)

- Supports legacy serial-based configuration application

- Supports remote file transfer

- US, Canada, IECEE, and CE approvals

- Built-in surge protection

All versions of the 9810 miniRTU support the following data protocols:

- Ethernet (OPC UA & Modbus TCP)

- RTU Slave (for ViewRTU)

- Modbus Master and Slave

- TLS (Veeder-Root)

- Enraf (GPU & FlexxConn)

- HLS (Hectroic Optilevel)

- Debug communications

- Honeywell Engauge

Serial Module:

- Provides up to three RS-485 connectors or up to two RS-232 connectors for serial communications

- Supports RTU protocol for legacy FuelsManager systems

GPU Bi-Phase Mark Module:

- Provides two BPM channels, each with two connectors for field termination

- Supports Honeywell Enraf GPU Bi-Phase Mark loops

Mark/Space Module:

- Provides one Mark/Space channel with two connectors for field terminations

- Integrates to multiple Varec transmitters, and third-party manufacturer Mark/Space transmitters

Tankway Module:

- Provides one Tankway channel with two connectors for field termination

- Supports L&J Tankway tank gauge transmitter

Module Architecture

- CPU: 480 MHz

- CPU Memory: 64 MB flash / 128 MB SDRAM

- Host Communication Ports: Up to 3, Type: USB-B/RS-232 or RS-232/RS-485, Protocol: RTU and Modbus Slave

- TCP / IP Communications: (1) 100 Mbps Ethernet interface using OPC UA over TCP/IP, Modbus TCP Server, Modbus TCP Client

- Debug Port: User configurable to one of the serial channels

- Power Supply: DC Requirements: 20 – 60 VDC

- Surge Protection: Meets ANSI / IEEE standards

- Dimensions: 6.5” H x 7.7” W x 3.3” D

- Material: Aluminum

- Mounting: Panel (wall) or DIN rail mounted

- Ratings: IP40 / IP 66 w/ optional enclosure

- Ratings: NEMA 4 Environmental

- Operating Temperature: -40 °F to +176 °F (-40 °C to +80 °C)

- Storage Temperature: -40 °F to 212 °F (-40 °C to 100 °C)

- Humidity: 5 to 95% RH (non-condensing) Intelligent Communication Interfaces

All versions of the 9810 miniRTU support the following data protocols:

- Ethernet (OPC UA & Modbus TCP)

- RTU Slave (for ViewRTU)

- Modbus Master and Slave

- TLS (Veeder-Root)

- Enraf (GPU & FlexxConn)

- HLS (Hectroic Optilevel)

- Debug communications

- Honeywell Engauge

9814 Serial Module:

- Provides up to three RS-485 connectors or up to two RS-232 connectors for serial communications

- Supports RTU protocol for legacy FuelsManager systems

9812 GPU Bi-Phase Mark Module:

- Provides two BPM channels, each with two connectors for field termination

- Supports Honeywell Enraf GPU Bi-Phase Mark loops

9815 Mark/Space Module:

- Provides one Mark/Space channel with two connectors for field terminations

- Integrates to multiple Varec transmitters, and third-party manufacturer Mark/Space transmitters

9816 Tankway Module:

- Provides one Tankway channel with two connectors for field termination

- Supports L&J Tankway tank gauge transmitter

Datasheet

Technical Specifications

Manuals

Brochure

Applications

Applications

Compatible Communications

Compatible Communications

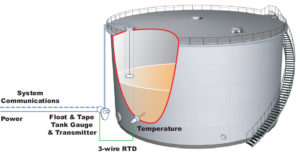

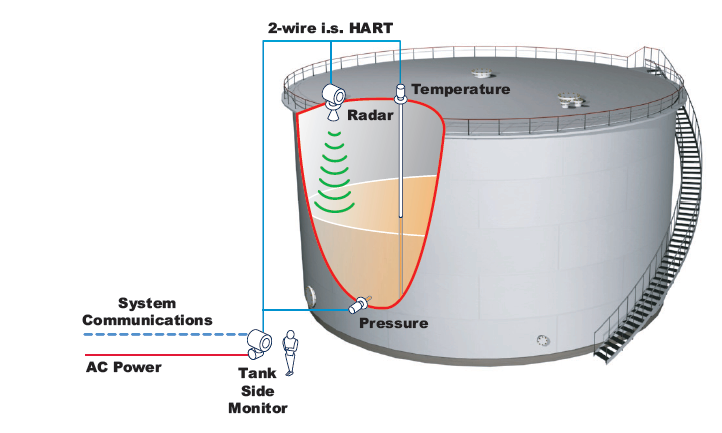

The NRF81 TSM is typically installed at the bottom of the tank for ease of access and allows access to all connected tank sensors. collects the measured values and performs several configurable tank calculations. All measured and calculated values can be displayed at the on-site display. Also, through a field communication protocol, the NRF81 TSM can transfer the values to an inventory control system like FuelsManager.

The NRF81 TSM is typically installed at the bottom of the tank for ease of access and allows access to all connected tank sensors. collects the measured values and performs several configurable tank calculations. All measured and calculated values can be displayed at the on-site display. Also, through a field communication protocol, the NRF81 TSM can transfer the values to an inventory control system like FuelsManager. Versatile Tank Gauging

Versatile Tank Gauging Accurate Results

Accurate Results

On Your Tank

On Your Tank

FMR60 RTG, with an accuracy level of ±1 mm for liquids and ±3 mm for solids, is a 2-wire technology that reduces tank wiring costs and allows easy implementation into existing systems. With its non-contact measurement, the tank’s top is almost independent from product properties.

FMR60 RTG, with an accuracy level of ±1 mm for liquids and ±3 mm for solids, is a 2-wire technology that reduces tank wiring costs and allows easy implementation into existing systems. With its non-contact measurement, the tank’s top is almost independent from product properties. Worldwide Approvals

Worldwide Approvals