MOBILE AUTOMATED RATIO CONTROL

Measure, monitor and manage acid blending to optimize hydraulic fracturing.

The Mobile Automated Ratio Control (MARC) provides a safe, accurate and consistent acid blend based during hydraulic fracturing. MARC not only monitors the blend ratio during the frac stages, it also monitors and provides the acid solution source data. Level depth, volume and temperature of the acid solution are also available in the system. MARC includes an option to calculate acid trailer volume to ensure there is enough product left for the next stage.

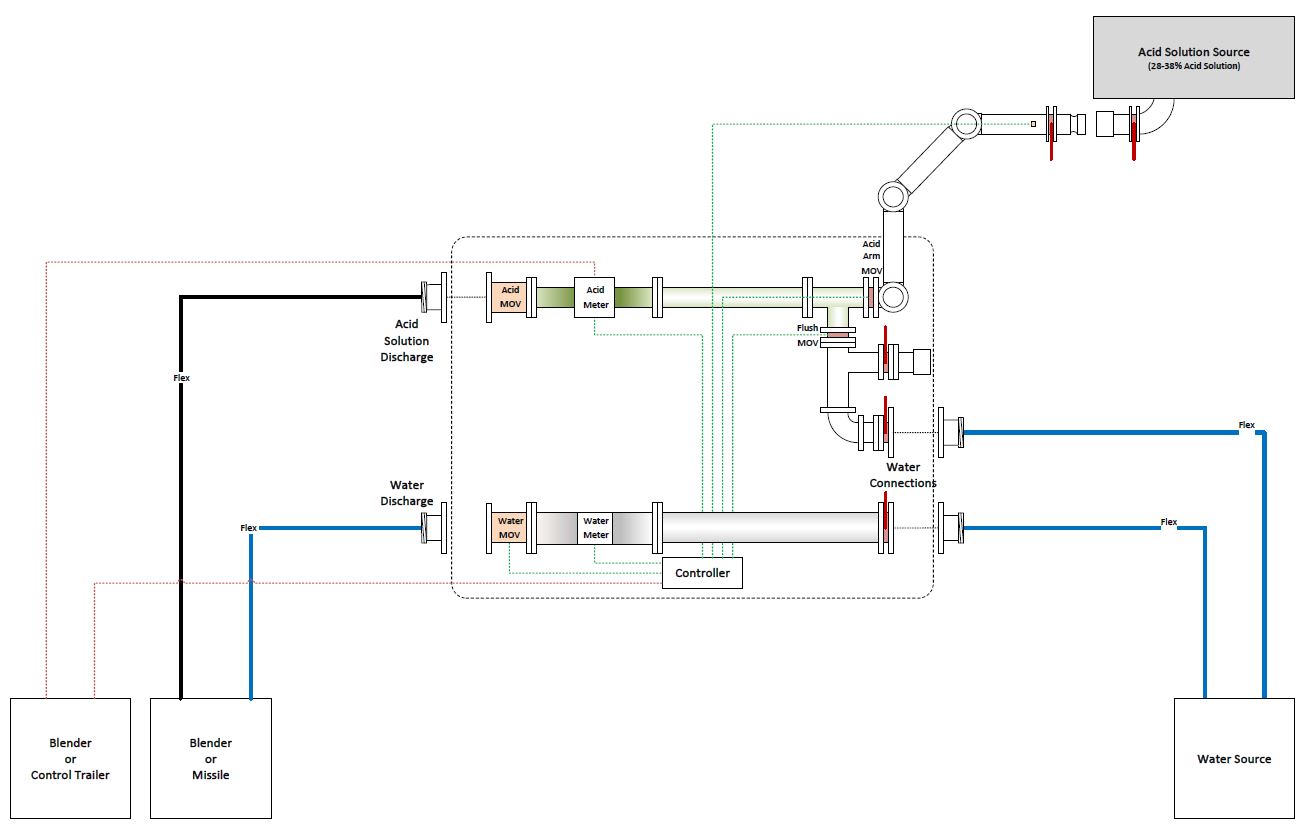

This system is designed to integrate into existing field equipment as it can be placed between the drop pump (or blender) and the water and acid solution sources. Once integrated, field operators can easily follow the on-screen, step-by-step directions to customize the acid blend for every frac stage.

Improved efficiency and safety

With MARC, hydraulic fracturing sites can eliminate manual acid delivery processes and improve safety. Field operators will no longer need to be in close proximity to lines carrying acid or acid equipment during an active frac stage. Site operations will benefit from removing human errors during the ratio blending process, resulting in a more efficient acid ratio delivery.

Once field operators determine what the acid ratio and drop size should be, MARC ensures the ratio is accurately delivered. This accurate, consistent and efficient blending provides cost savings by reducing acid waste.

Reasons to deploy MARC at your site:

- Faster and more efficient frac stage process by removing the guesswork

- Acid ratio is automated during blending process

- Reduced costs by preventing excess acid usage

- Reduced manpower for onsite labor

- Protects the environment from excess acid

- Safe access to PLC, valves and connectors

- Eliminates need to handle acid lines or equipment during blending process

- Fluid level measurement is automated on the skid, eliminating manual processes

- Integrates with existing fracking equipment through common connectors, hoses and valves

- Less manual handling of other fracking equipment extends the longevity, reduces maintenance

- Internal components are coated for maximum protection against acid corrosion

Key Features

- Designed to permit desired acid solution ratio through combined acid and water sides

- Monitors acid solution source content, no need to measure between runs

- Manages desired acid solution ratio through combined acid and water sides

- Live real-time progress of drop data provided and adjustments to ratio during drop is allowed

- Skid automatically shuts acid source at end of drop and flushes the skid of all acid every run

- Arm is flushed during final drop at each site, and clears entire skid, including arm, for transport (not DOT hazardous)

Deployment Options

- Skid or trailer Skid

− Forklift pockets for heavy lifters commonly used at well sites

− Trailer – Simple double-axle trailer that is easily transported

- Pull through or pump included

− Pull through – Unit can be dropped into the current setup to regulate ratio of acid solution and water lines

− Pump – Unit comes with pump and provides fully blended solution on every connection, sending directly to missile or elsewhere

- Choice of hose fitting type(s)

− Bolt-on flanges make it easy change or replace hose fitting connections; fitting options or spares available to order

- Acid solution meter pulse feed

− For existing solutions with a meter and acid solution meter data is needed

- Control trailer interface

− Custom interface for each operation enabling monitoring and control from the control trailer